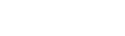

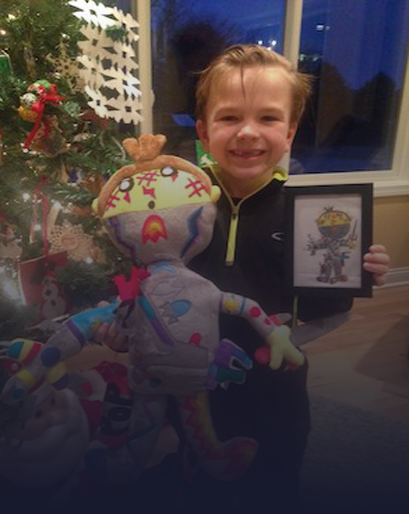

About

Our client required an online software to manage the warehouses at multiple

geographical location along with stock management system. Warehouse management system was

required to integrate with existing order management system that client was already using.

To manage the warehouses and stock, client also needed an android application to run on

android scanner as well as on android mobile. For this, they contacted Irasys and teamed

up to commence the application development. We developed a complete solution from scratch

that made it easier for the Client to manage the stock at multiple geographical locations.

Our solution enabled them to quickly create a warehouse and define the inner architecture

of number of shelf / rows / sections etc. The delivered warehouse management solution

enabled them to self-generate the unique bar codes labels scalable by the android application.

As of March 2019, all these services were delivered with the help a dedicated team of 5 members

through full-time engagement model.

Business Requirements

Our client, a garment manufacturing unit had an existing order management

system which was doing fine but the major problem they were facing was to manage the stock

and the warehouses. Being a garment manufacturing unit, they had to manage the raw materials

and stocks from their customers as well as their own. As they were getting multiple orders daily

form their client’s sales representatives selling across the globe, they had to manage

the raw stock and materials for each customer. Moreover, some of their customer wanted

to use them as warehouse service provider. As per the business requirement there were two

possibilities:

- - Either the customer will ask them to provide warehouse services to keep

his own stock and whenever an order comes, manufacturing unit will fetch out the raw

stock / material from the exiting stock customer had or

- - The manufacturing unit own the raw stock /materials for the any order

that comes from the customer that do not own any raw stock / materials. Also, the client

wanted an interface for each of the customer to look at the stock level and notify them

when the stock reaches to a predefined range.

Some of their customers also wanted to use a service where they can allocate their stock to

be used by others specially those who don’t own any stock or raw material with manufacturing unit.

Lastly, they wanted most of the process to be managed by android scanner or android mobile phone.

A web-based solution and Android app to offer warehouse and stock management

Integration with existing order management system:

Our web-based solution is well integrated with client’s existing order management system.

All order that come through their customer directly goes to warehouse and the warehouse

staff then manages the order accordingly using the android scanner / mobile app.

Web based solution

Our web based solution is integrated with their existing order management system. Any

order that comes thought their customer goes directly to the warehouse user

and accordingly the warehouse user performs further action based on the order received.

An email notification system tells warehouse manager what is next in the row and along with

this, a job notification also goes to handheld device where the app is installed. Customer

and their sales representative can use web application to keep a track of stock level.

Customer can also allocate the stock he owns to any other customer.

The solution has been divided into various modules

Access control system: This module is for admins only so they can allocate required

modules to the customers. Modules are allocated on role basis.

Users: To add/edit/delete any user for warehouse and stock management

system

Warehouses: To add/edit/delete a warehouse. Admin and allocated user can only

work with this module. Admin can create warehouse for any location and can allocate users to these

warehouses.

Manage Warehouse: Warehouse manager can use this module to architect any warehouse.

He can create as many rows he want and add number of shelves within it. Then for each shelf he can create

number of rows and then sections for each row of a particular shelf. Each section then is automatically

assigned a unique barcode that cab be scanned by the android application. Each unique section asks a

pick location.

Stock management: Customer can add/edit stock and allocate the stock he owns

to any other customer he wants to sell. Customer adds stock to the system and system take it as

expected stock to be received from the customer to manage within the warehouse. When customer add

stock into the system, our system notifies via email with attached receiving note to warehouse manager

that stock has been added by a particular customer pending to be received on a particular date.

System also sends email to print server and it prints the stock receiving note at warehouse.

Mobile application

Receive stock: For every stock added to our system generates a receiving note.

Every receiving note contains a unique barcode on the top along with customer’s

information who added the stock. Mobile user can scan the barcode once the stock

reaches to warehouse that gives him information on number of pieces to be received

against the particular receiving note. User starts receiving the stock by scanning

the bar codes on the stock individually. If in case the received stock numbers do

not matches with numbers mentioned on receiving note, our system sends a discrepancy

email to customer and the admin and also keep a record of it to generate the reports

later.

Manage stock into the warehouse: Once stock is received, mobile user

can use the application to allocate stock items their unique section, that helps

manage orders later on.

Pick up stock: As the order received from a particular customer,

our system generates an order pick up note and send it to warehouse manager.

Also print server prints this pickup order note into the warehouse. Application

user then scans the barcode on the note and accordingly picks up the

items mentioned into the pickup order note.

Reports: To generate different stock reports